Understanding Utility Mark Codes: The Key to Safer, Smarter Construction and Excavation

In the world of construction and excavation, precision isn’t just a best practice—it’s a necessity. One of the most overlooked yet critically important aspects of pre-construction planning is understanding utility mark codes. These standardized markings, often color-coded and abbreviated, offer essential information about what’s beneath the surface. Misinterpreting or ignoring them can lead to costly delays, service interruptions, environmental hazards, and, most importantly, serious injury or loss of life.

Whether you’re breaking ground on a small residential project or a major civil infrastructure job, knowing how to read and interpret utility mark codes can significantly improve both efficiency and safety on the job site.

At Precision Services Unit, we prioritize safety and proactive planning. The best way to prevent utility strikes? Call 811 before you dig!

Why Utility Mark Codes Matter

Before any shovel hits the ground, professional utility locating services use a standardized set of codes and colors to mark the presence of underground utilities. These markings are not arbitrary—they’re a universal language of risk and responsibility.

Understanding these codes allows construction and excavation crews to:

-

Avoid Striking Critical Infrastructure: Accidentally hitting a fiber optic cable (FO), gas line (G), or high-voltage electric conduit (E) can shut down services for entire neighborhoods or create dangerous conditions.

-

Work More Efficiently: Knowing the layout of subsurface utilities helps project managers sequence tasks smarter, avoid redundant potholing, and reduce rework.

-

Protect Workers and the Public: Misidentifying a petroleum line (P) or high-pressure steam conduit (STM) can have explosive consequences. Recognizing and respecting these utilities keeps everyone safer.

Key Utility Mark Codes You Need to Know

These abbreviations indicate what type of utility or facility is present below the surface:

-

CH – Chemical

-

FO – Fiber Optic

-

LPG – Liquefied Petroleum Gas

-

RR – Railroad Signal

-

SD – Storm Drain

-

STM – Steam

-

SS – Storm Sewer

-

TS – Traffic Signal

-

W – Reclaimed Water (Purple)

-

E – Electric

-

G – Gas

-

P – Petroleum Products

-

S – Sewer

-

SL – Street Lighting

-

SP – Slurry System

Being familiar with these allows crews to make informed decisions about safe digging techniques and machinery usage.

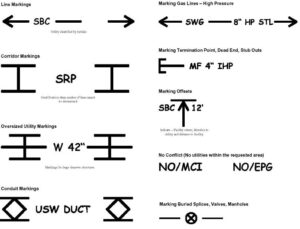

Underground Construction Descriptions – What Form Does It Take?

These descriptors help clarify the type of underground feature present:

-

Manhole – Indicates a vertical access point to underground utilities.

-

PB – Pull Box, used to manage electrical cable junctions.

-

Structure / STR – Refers to inlets, vaults, lift stations, or similar installations.

-

Radius – Notes the curvature of pipes or cables, which is critical for boring operations.

-

Transmission Facility – High-capacity conduits like main water lines or electrical trunks.

Knowing whether you’re dealing with a small conduit or a large structure helps in choosing proper excavation methods and equipment.

Infrastructure Materials – What’s It Made Of?

Identifying the material of a buried utility affects everything from excavation technique to repair methods:

-

ABS – Acrylonitrile-Butadiene-Styrene

-

CI – Cast Iron

-

CML / CMC – Cement Mortar Lined / Coated

-

CMP / CPP – Corrugated Metal / Plastic Pipe

-

CWD – Creosote Wood Duct

-

MTD – Multiple Tile Duct

-

RCB / RCP – Reinforced Concrete Box / Pipe

-

RF – Reinforced Fiberglass

-

STL – Steel

-

ACP – Asbestos Cement Pipe (requires special handling)

-

CU – Copper

-

HDPE – High-Density Polyethylene

-

PLA – Plastic

-

SCCP – Steel Cylinder Concrete Pipe

-

VCP – Vitrified Clay Pipe

Understanding material types is essential for determining load-bearing capabilities, choosing the right cutting tools, and following environmental or health regulations (especially with ACP).

Uniform Color Codes

Uniform Color Codes were developed by the American Public Works Association (APWA) for the temporary marking of underground utilities. These “safety colors” were formalized by the American Standards Institute (ANSI) as Safety Color Code Z535.

- Red: electric power lines, cables, conduit and lighting cables

- Orange: telecommunication, alarm or signal lines, cables or conduit

- Yellow: natural gas, oil, steam, petroleum or other flammables

- Green: sewers and drain lines

- Blue: drinking water

- Purple: reclaimed water, irrigation and slurry lines

- Pink: temporary survey markings, unknown/unidentified facilities

- White: proposed excavation limits or routes

The Bottom Line: Safety and Efficiency Go Hand-in-Hand

Interpreting utility mark codes isn’t just a task for locators—it’s a foundational skill for foremen, operators, laborers, and safety officers. The stakes are high: underground utility strikes are a leading cause of serious construction site incidents, many of which are completely avoidable.

Proper training in utility markings empowers your team to:

-

Plan smarter

-

Dig safer

-

Finish faster

So before you break ground, make sure your crew breaks out their utility code knowledge first.

Precision begins with awareness. Safety begins with understanding.

📞 Digging soon? Call 811 before you start!

#KnowWhatsBelow #Call811 #ExcavationSafety #ConstructionBestPractices #PrecisionServicesUnit